Mattrix’s simple OLET technology platform significantly reduces the cost of displays by enabling the manufacturing of OLED displays using recycled LCD manufacturing lines. This is the next evolution in OLED technology.

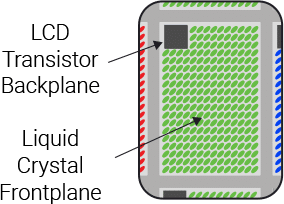

AMOLED is a product differentiator featuring the deepest blacks and most vibrant colors. However, conventional AMOLED manufacturing requires a complex, expensive backplane to drive the emissive OLED frontplane.

Mattrix circumvents what is known as the “AMOLED backplane problem” and allows LCD-TFT array lines to be recycled for AMOLED manufacturing.

AMOLED: Active-Matrix Organic Light-Emitting Diode

Backplane: This circuitry supplies current to the pixel and acts as the pixel’s internal “dimmer switch”

Frontplane: Converts electrical current to light

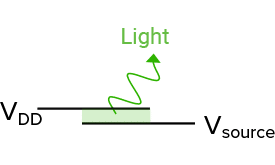

Supplies current to pixel and acts as the pixel’s internal “dimmer switch”

Converts electrical current to light.

While the conventional OLED frontplane provides better contrast than conventional liquid crystal frontplane, a complex, expensive, and large backplane is needed.

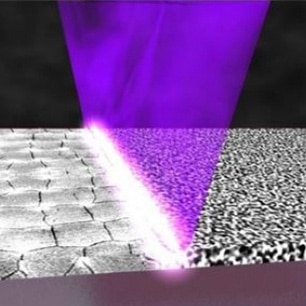

Mattrix has designed a new, simple pixel architecture using an innovative light-emitting transistor.

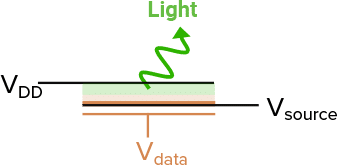

This simple and highly efficient emissive pixel is enabled by Mattrix’s proprietary OLET (Organic Light-Emitting Transistor) technology:

The conventional OLED simply emits light and requires a separate complex backplane to control the drive current.

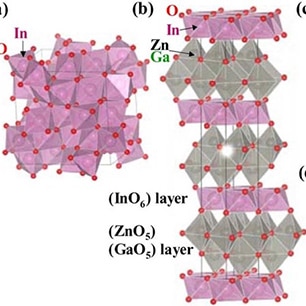

Mattrix’s OLET combines current control with light emission by integrating 3 components into one highly stable device

Low cost OLED materials. Compatible with next generation emissives.

Uses recycled LCD-TFT manufacturing lines. Accelerates adoption of inkjet printing and roll-2-roll processing

Leverages mature manufacturing: Fewer steps. Higher yields.

Reduced Image Sticking

Highest Brightness & Contrast

Fully Transparent

Longer Lifetime

Truly Bendable